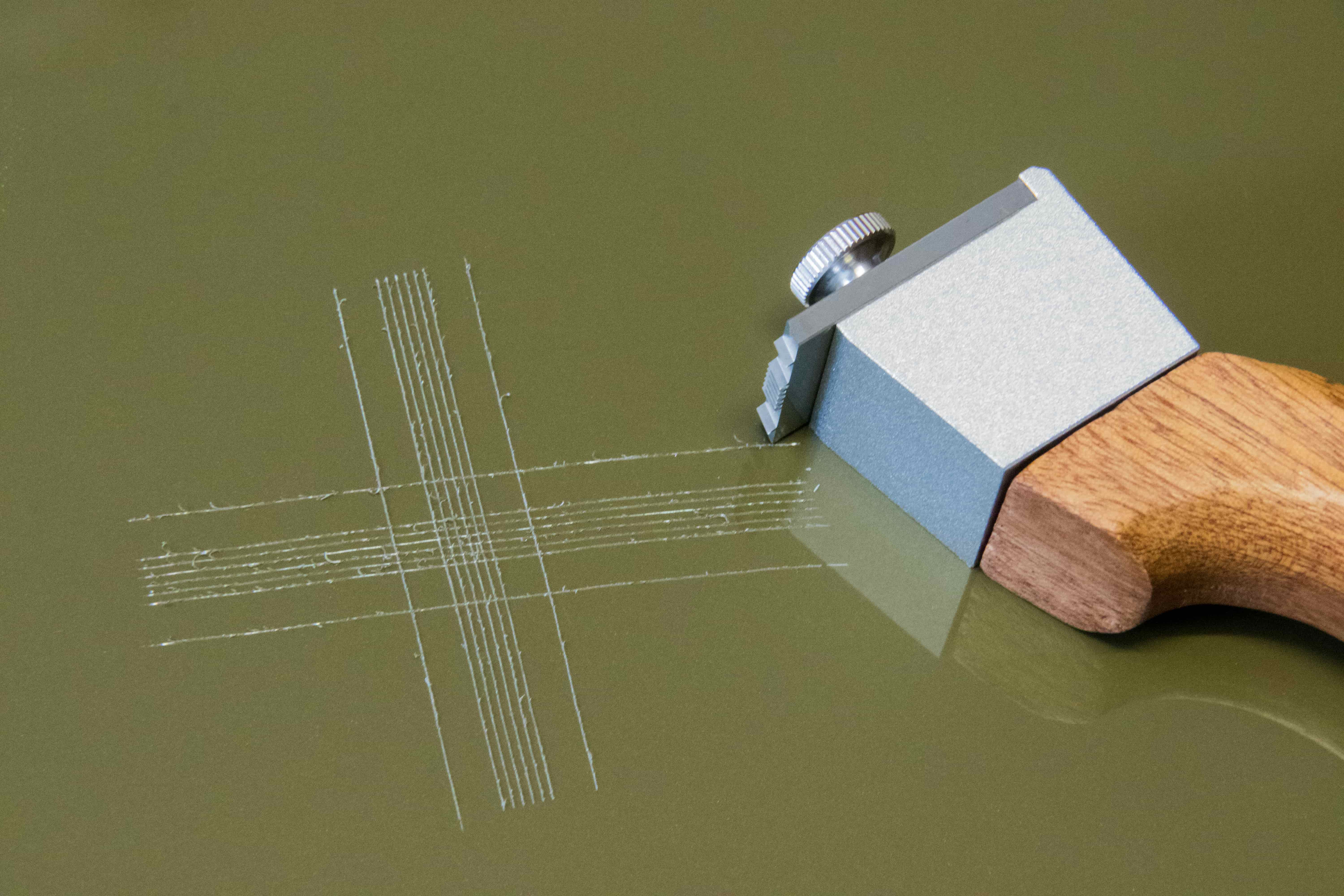

Crosshatch Cutter (rotable) according to DIN EN ISO 2409

Description:

The Crosshatch Cutter is designed and manufactured according to the standards DIN EN ISO 2409, GB / T 9286, BS 3900 E6 and ASTM D3359.

The rotable function enables even pressure on all blades during use, which leads to a higher reproducibilty and also is more user friendly.

Technical specifications:

Gap (mm): 1

Blades: 6

Squares after cross cut: 25

Cutting Edges: 1

Coating Thickness (µm): 0~60

Item number: PG-2206/1S

Delivery Scope: Crosshatch Cutter (rotable)

Including manufacturer’s test certificate and 1 year warranty

Construction of the device:

This cross cutter (also called cross hatch tester or crosshatch cutter) consists of a handle with a cutting tool. The cutting tool has one cutting edge, once it becomes blunt, it can be changed to a new cutting tool (cutting head). The cutting edge is made up of 6 blades.

We suggest changing the cutting edge after about 700 cuts by replacing the cutting tool with a new one.

The distances between the blades are either 1.0 mm, 1.5 mm, 2.0 mm or 3.0 mm.

General:

The standard DIN EN ISO 2409 (cross-cut test) specifies the following:

The spacing of the cuts in each direction shall be equal and shall depend on the thickness of the coating and on the type of substrate as follow:

up to 60 µm:

1 mm spacing, for hard (e.g metal and plastics) substrates;

up to 60 µm:

2 mm spacing, for soft (e.g wood and plaster) substrates;

61 µm to 120 µm:

2 mm spacing, for both hard and soft substrates;

121 µm to 250 µm:

3 mm spacing, for both hard and soft substrates;

The cross-cut test is not suitable for coatings of total thicknesses greater then 250 µm

Crosshatch Cutter rotable head