Dryingtime Recorder

Description:

A coating’s drying time or drying process can be determined with the dryingtime recorder.

The test substance is applied on a glass strip (for example by using a cube applicator and glass strip holder with stop point). The coated glass strip is then inserted into the drying time recorder as fast as possible and the recorder started immediately.

Now the pin moves along the coated glass strip with a defined speed (adjustable from 1 h to 48 h for a complete track) and leaves a groove in the wet film.

The device can now be left unattended.

The groove the pin leaves on the coating is evaluated: The individual drying phases as well as the position where the pin no longer leaves a groove can be determined. From here the coating material is dry.

The drying time (no visible groove) and the individual drying phases can be read off with the help of the scale on the device.

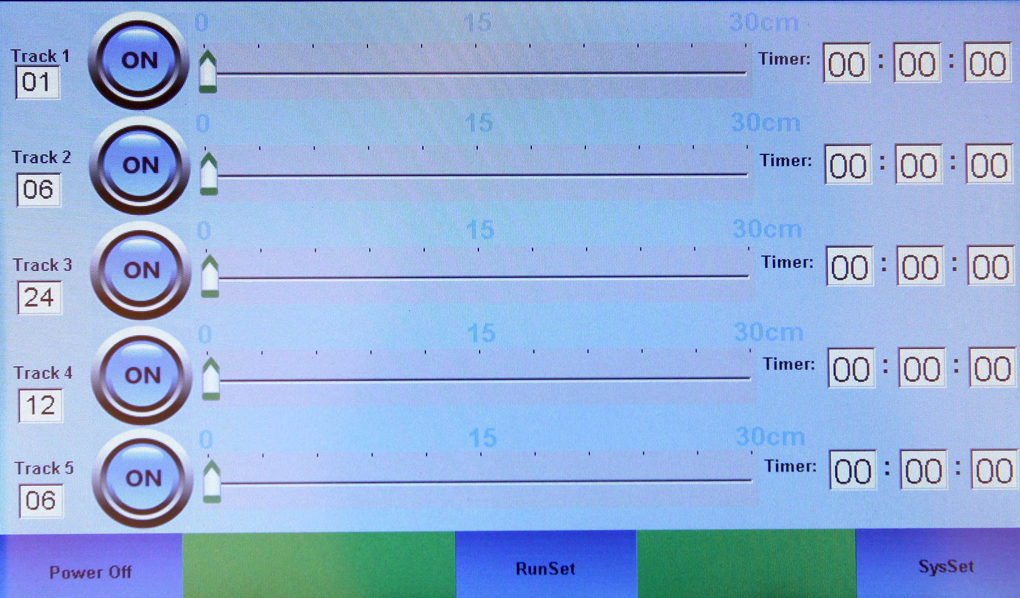

The device has 10 tracks. Two tracks are always operated together.

Tracks 1+2 can be set from 1h to 48 h.

Tracks 3+4, 5+6, 7+8, 9+10 can be set to 6 h, 12 h, 24 h or 48 h.

Technical specifications:

Dimensions: 550 x 530 x 200 mm

Tracks: 10

Length of tracks: 300 mm

Pin drive: 5 motors: 1 motor for 2 tracks

Drying times track 1+2: 1 h – 48 h

Drying times track 3-10: 6, 12, 24, 48 h

Item number: PG-1815

Delivery Scope:

• 1x Glass strip holder with stop point (PG-1815/P/003)

• 10x Glass strip (PG-1815/P/005)

• 1x Cube applicator 37/75 µm (PG-1805/1)

Standards: ASTM D5895, ISO 91117-4 and DIN EN 14022

Including manufacturer’s test certificate and 1 year warranty