Crosshatch Cutter according to DIN EN ISO 2409

Description:

The Crosshatch Cutter is designed and manufactured according to the standards DIN EN ISO 2409, GB / T 9286, BS 3900 E6 and ASTM D3359.

Technical specifications:

Gap (mm): 1

Blades: 11

Squares after cross cut: 100

Cutting Edges: 8

Coating Thickness (µm): 0~60

Item number: PG-2202/2S

Delivery scope: Crosshatch cutter, hexagonal screwdriver

Including manufacturer’s test certificate and 1 year warranty

Construction of the device:

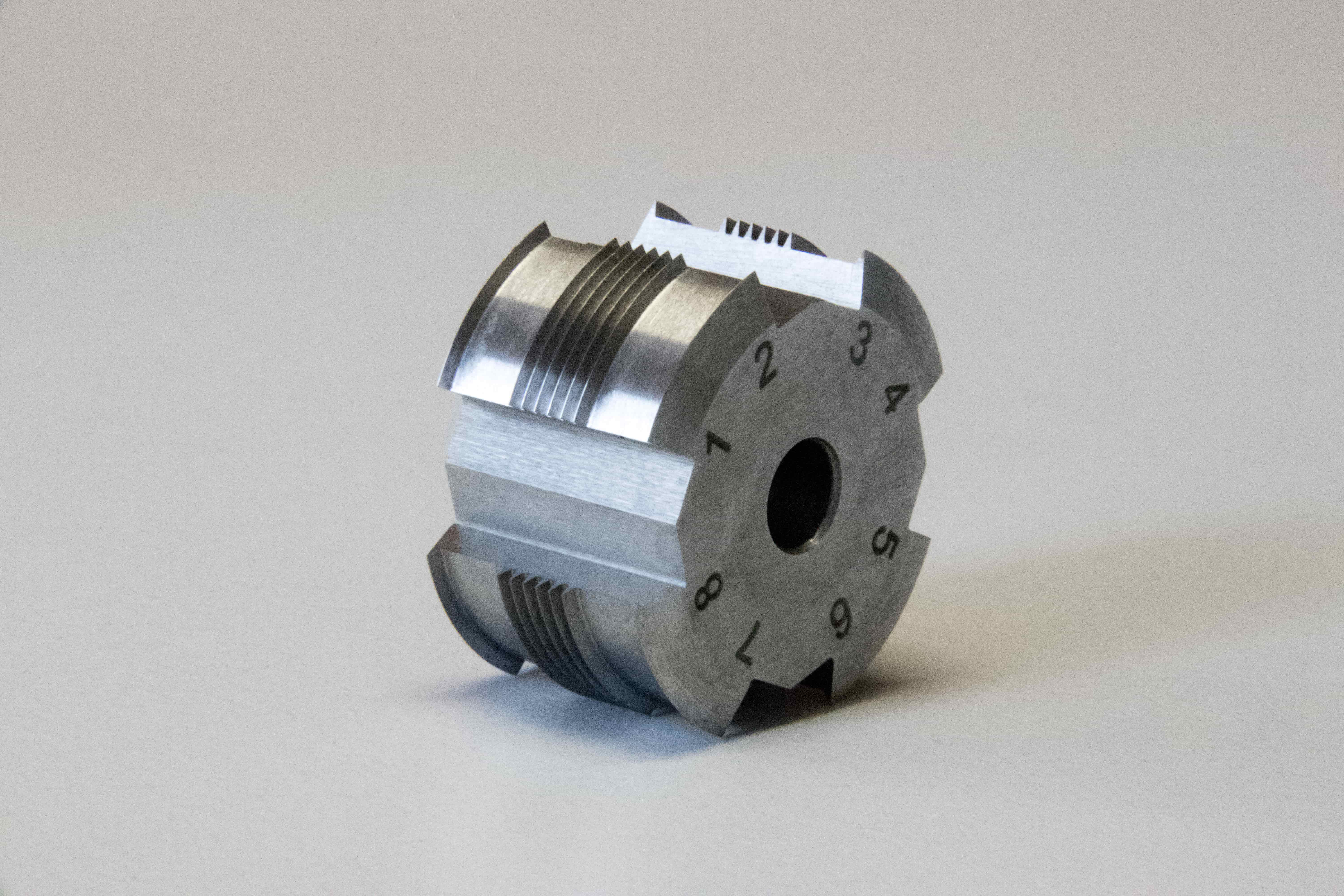

The cross cutter (also called cross hatch tester or crosshatch cutter) consists of a handle with a round cutting tool. There are 4 knives around the cutting tool, which can be used on both sides (= 8 cutting edges). Each cutting edge is made up of 11 blades. The cross cut is made with one of the 8 cutting edges, the other 7 are used as soon as the cutting edge becomes blunt.

We suggest changing the cutting edge after about 700 cuts using the allen key to loosen the cutting tool and spinning the cutting tool until one of the remaining cutting edge is in position.

If all 8 cutting edges were each used for approx. 700-1000 cross-cuts, it is recommended to replace the complete cutting tool with a new one.

The distances between the blades are either 1.0 mm, 1.5 mm, 2.0 mm or 3.0 mm.

General:

The cross-cut test is used for single-layer as well as multi-layer varnish systems and provides information about the adhesion of the varnish to the substrate (in the single-layer construction) but also about the intermediate-layer adhesion in multi-layered systems (primer / basecoat / clearcoat).

The standard DIN EN ISO 2409 (cross-cut test) specifies the following:

For a total layer thickness between 0 and 60 μm and a hard substrate, such as metal or plastic, the cross cutter with a distance of 1 mm has to be used.

For a total layer thickness between 0 and 60 μm and a soft substrate such as wood or stucco, the cross cutter with a distance of 2 mm has to be used.

For a total layer thickness between 61 and 120 μm, the cross cutter with a distance of 2 mm has to be used for all substrates.

For a total layer thickness between 121 and 250 μm, the cross cutter with a distance of 3 mm has to be used for all substrates.